Technicians at First Choice Dental Lab save 30 hours a week with Oqcam’s AI

Old habits die hard. Matt Cushing, owner and founder of First Choice Dental Lab, knew this full well when he decided to introduce new software in his CAD/CAM department. He also knew this mindset would change.

“When you have dental technicians who are comfortable with a process, you’re going to get resistance to new software. I expected that,” Cushing says. “But once they saw the benefits and the end game, I would get their buy-in,” he says.

The lab replaced previous CAD/CAM software with Oqcam, AI-powered software for dental labs. While the move was initially met with reluctance, today staff relish the fact that AI is doing the tedious part of their job. “They’ve seen that it frees them up to focus on other tasks and saves them time,” Cushing says.

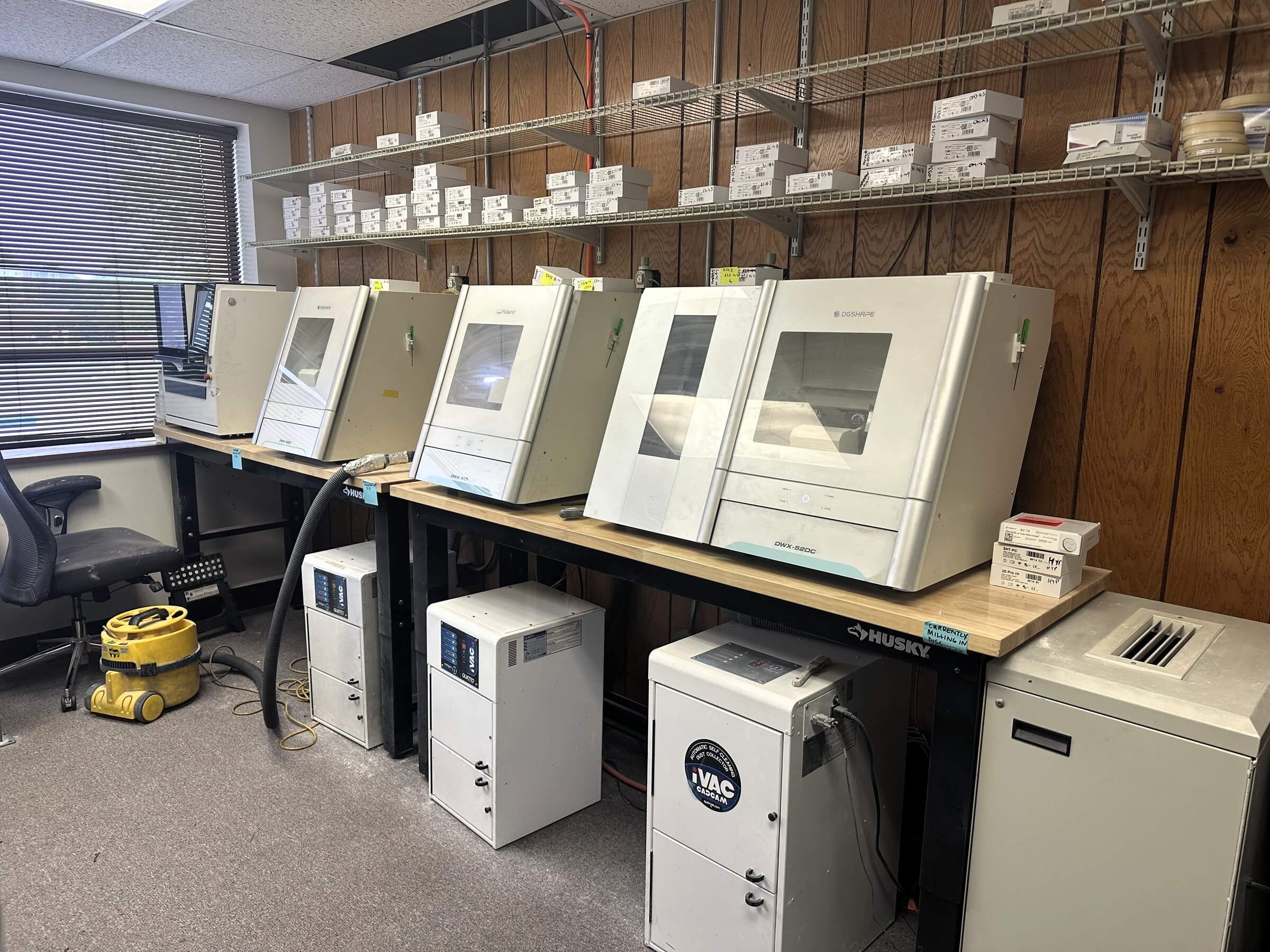

Founded 17 years ago, First Choice Dental Lab offers a full range of services, making everything from crowns and bridges to dental implants and splints. Today it employs 30 people, three of whom work in the CAD/CAM department.

Oqcam helped them address a major difficulty – shortage of skilled personnel. Training programs do not produce enough technicians. Plus, the existing staff have had to learn new technology used for digital manufacturing and CAD/CAM.

Doing more with the same resources

The solution, as Cushing saw it, was to do more with what the lab had. Any piece of equipment or tool that would allow his technicians to increase efficiency was carefully considered. That’s what attracted him to Oqcam.

And the AI-powered software delivered. The volume of jobs that four people used to handle can now be handled by three. “Oqcam has freed up my technician’s time. We’ve probably saved around 30 hours a week in labor, which allows our technicians to spend their time on other tasks,” Cushing explains.

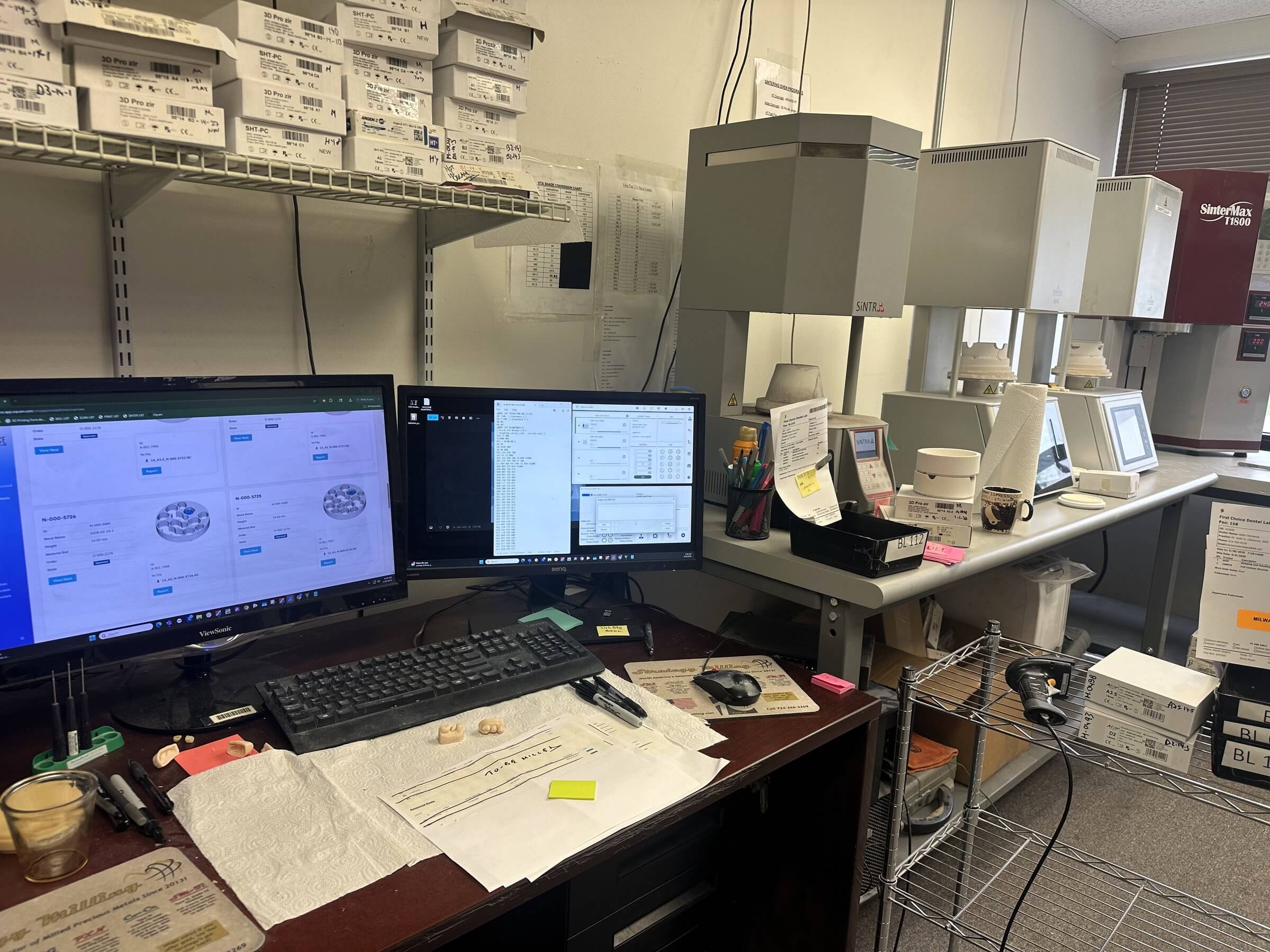

Repetitive tasks, like dragging and dropping files and orienting parts on a puck or on a build plate, are now done by AI. Meanwhile, technicians are putting their skills to better use, like esthetic design or finishing a crown.

“The key takeaway for any lab owner or manager is that Oqcam frees up technicians for higher value-added tasks. It’s not an attempt to reduce the team, it’s to allow them to focus on better tasks,” he concludes.

Technicians used to spend much more time on repetitive tasks in milling. One person would spend a good chunk of their day grabbing the files, loading them, making adjustments, and waiting for calculations. The same person would also be managing stock and searching for the right puck. The process was manual, slow and tedious.

Today a significant portion of that process is automated. “Once we drag the files into our Oqcam folder and launch nesting, the technician can walk away and work on something else, like implants. We’ve saved a lot of time in that process alone. Oqcam selects the right puck, orients the crown and puts on the pins. Those tasks take small amounts of time, but they add up very quickly. That’s where automation really helps,” Cushing says.

Efficient stock management

The lab has also reduced material use and inventory. “Our zirconia spend and zirconia inventory have gone down since we got Oqcam because it uses zirconia pucks more efficiently and notifies us when we’re about to need a new one, so we order them only when we need them. We’ve seen cost savings on both those fronts,” Cushing says.

Another advantage of Oqcam is starting all the mills at once. It used to be a one-at-a-time approach where a technician would nest one job, wait for the software to propose a milling strategy, and then put it in the mill. Only once the first mill got going could they start the second one. By starting all the mills at the same time, staff can better plan the order of the jobs. They can see what job is going to be the most time-consuming, and line up the jobs strategically.

3D printing workflows have undergone a similar transformation. Oqcam’s automation reduced the time spent placing files on the build plate, orientation, and supports placement. Technicians simply drop the files in the Oqcam folder, and it immediately creates print jobs.

And the quality of those printed parts has become more consistent. Cushing describes 3D printing as the most finicky process in the lab, where the manufacturer’s recommendations need to be followed to the letter. “We have reduced human error because Oqcam automates a lot of the process, and we have seen a lot more consistency. The success rate for our printing has gone significantly up,” he says.

Doing more with AI

Support was a top concern for Cushing when considering switching out software. As Oqcam’s team provided quality training and help, it was easy to get the lab on board with using AI. “In the lab we say that people aren’t going to be replaced by AI or technology. They’re going to be replaced by people that will work with AI and technology. We ask staff to commit to learning those things” he concludes.

Other dental labs stand to benefit from Oqcam in his view. “The efficiencies, the savings that it introduces are incredibly valuable. They can be incredibly valuable to everyone from a small lab all the way up to a large production lab,” he says.

Subscribe to our newsletter

Get our best content straight in your inbox

Oqcam

Oqcam